- How to calculate paper bag material cost ?

- Lucy Wang

- June 29, 2022

Nowadays , more and more countries start ban plastic . The environment-friendly bag become more and more popular in all over the World ,especial paper bag .

If need invest the paper bag production line , the first important thing is study target market and find out the popular bag type and size range .

Then checking which type machines can do it and how many machines need in whole paper bag production lines . We ZHEJIANG KETE MACHINERY CO.LTD are professional supplier of roll feeding paper bag making machines in China .We supply almost all machines of whole paper bag production line machines . Include full auto shopping paper bag making machine which with inline handle making , food paper bag making machine for packing fast food ,such as KFC , bread , flour ,etc . Our machines also workable to add many optional functions : D-cut handle paper bag ( patch paper bag ) , bag with plastic window , add tape on bag top , inline printing ,and so on .

The related supporting machine such as paper slitting machine , paper laminating machine , paper coating machine , paper roll printing machines also can be offered by us .

Usually the material cost of each size paper bag will also important reference factors before start this project . How many paper material can be made with one ton paper ? And how many cost of each bag ?

Here we will share the solutions to calculate one bag with flat handle cost for reference .

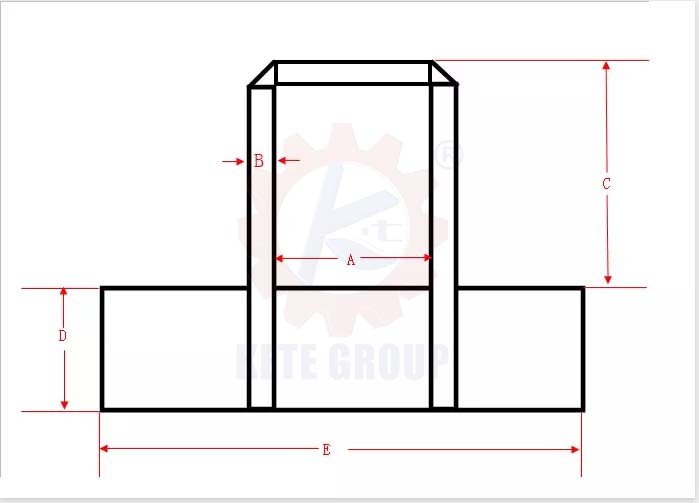

Flat handle rope width : 12mm , rope length :352mm , Flat handle paper patch size W50mmx L152mm

If the paper thickness 100gsm, and Let’s say the price of paper is USD1700/ton .

1 . Calculate Bag body withou handle cost :

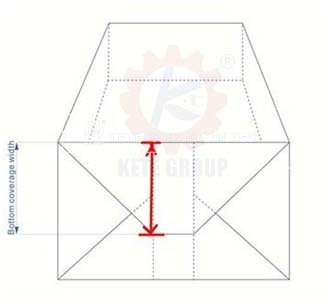

Bag bottom cover width = Bottom width( side width) /2 +bottom gluing width =160mm/2+20mm=100mm

(Mark :usually the bottom gluing width is about 20-30mm , depending on bag size , more big size gluing part more wider .)

One bag need take one pcs paper size :

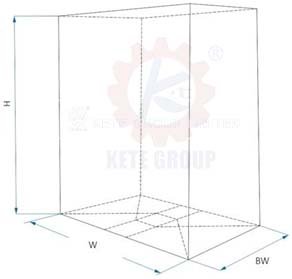

W ( same to Unwind paper roll width) =(Bag width + Side width)x 2+ side gluing width = (280mm+160mm)x2+30mm =910mm .

Length = Bag cutting length =Bottom cover width + bag height = 100mm+280mm=380mm

One bag body weight :W x L x paper thickness =910mmx380mm/1000000 x 100gsm=34.58g

So bag body cost = One bag body weight x paper cost

=34.58 g/1000000x USD1700/ton =USD0.058786

2. Calculate one pair flat handle cost :

² One pcs flat handle rope need take one pcs paper size :

W: Rope width x 4=12mmx4=48mm , L 352mm,

This one paper weightt = 0.048×0.352x100gsm =1.6896g

² One handle include 2 pcs paper patch,so paper patch weight :

W50mmx L152mm /1000000 x100gsmx 2pcs=1.52g

One pair flat handle weight :(1.6896g+1.52g ) x 2 =6.4192g

Therefore , one pair flat handle cost : (1.6896g+1.52g ) x 2 /1000000 x USD1700/ton =USD 0.0109

3. Calculate one whole Bag with flat handle paper cost :

Compelet one Bag with flat handle paper cost = bag body cost + flat handle part cost = USD 0.0109 + USD0.058786≈USD0.697

4. The quantity of bags can made with 1 ton paper (Uncounted waste cost):

1ton /1 bag weight =1000000g/(6.4192g+34.58g)≈24390pcs

Note : Above result all based on perfect production ,it not calculate waste parts cost . Just for reference only .

Do you like the post ? Share it now :