Description:

This Roll Feeding Square Bottom Paper Bag Manufacturing Machine uses roll-type paper to make square bottom paper bags without handles.

Performance and Characteristics:

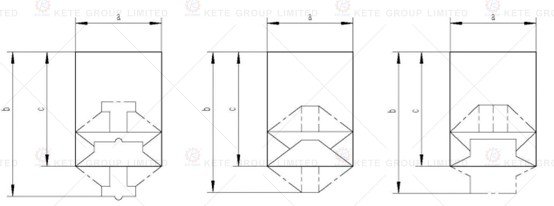

Model | KTPM-B450 | KTPM-B450A | KTPM-B450B |

Tube Length | 270-530mm | 300-630mm | 380-760mm |

Bag Width | 200-450mm | 220-450mm | 220-450mm |

Bottom Width | 90-180mm | 100-220mm | 80-230mm |

Paper Thickness | 70-150gsm | 80-150gsm | 80-150gsm |

Paper Feeding Speed | ≤90m/min | ≤90m/min | ≤90m/min |

Mechanical Speed | 30-200 pcs/min | 30-180 pcs/min | 30-150 pcs/min |

Paper Bag Making Speed | 30-180 pcs/min | 30-150 pcs/min | 30-120 pcs/min |

Paper Jumbo Roll Width | 610-1290mm | 670-1370mm | 630-1390mm |

Paper Jumbo Roll Diameter | Φ1300mm | Φ1300mm | Φ1300mm |

Paper Core Diameter | Φ76mm | Φ76mm | Φ76mm |

Inline Printing Function (Optional) | |||

Printing Color | 2colors/4colors | 2colors/4colors | 2colors/4colors |

Printing Length | 100-1360mm | 100-1360mm | 100-1460mm |

Printing Width | 270-530mm | 300-630mm | 380-760mm |

Printing Speed | 10-100m/min | 10-100m/min | 10-100m/min |

Color Register Precision | ≤±0.20mm | ≤±0.20mm | ≤±0.20mm |

Rubber Plate Thickness | 2.28mm+0.38mm 1.7mm + 0.38mm | 2.28mm+0.38mm 1.7mm + 0.38mm | 2.28mm+0.38mm 1.7mm + 0.38mm |

Working Air Current | 0.36m³/ min (0.5-0.8 MPa) | 0.36m³/ min (0.5-0.8 MPa) | 0.36m³/ min (0.5-0.8 MPa) |

Machine Power | 15kw 23.8kw (inline 2 colors) 27.4kw (inline 4 colors) | 17.5kw 23.5kw (inline 2 colors) 26.5kw (inline 4 colors) | 17.5kw 23.5kw (inline 2 colors) 26.5kw (inline 4 colors) |

Machine Weight | 9000kg 11500kg (inline 2 colors) 12000kg (inline 4 colors) | 10500kg 12500kg (inline 2 colors) 13000kg (inline 4 colors) | 10500kg 12500kg (inline 2 colors) 13000kg (inline 4 colors) |

Machine Size (LWH) | 10000x3800x2200mm 16400x5000x2500mm (inline 2 colors) 17700x5000x2500mm (inline 4 colors) | 12000x3800x2200mm 16500x5000x2500mm (inline 2 colors) 17800x5000x2500mm (inline 4 colors) | 12000x3800x2200mm 16500x5000x2500mm (inline 2 colors) 17800x5000x2500mm (inline 4 colors) |

Power Support | 3 Phase 220/380/440V 50/60HZ | ||

Touch screen :SCHNEIDER brand

PLC control system : LENZE brand